Introduction

What We Do

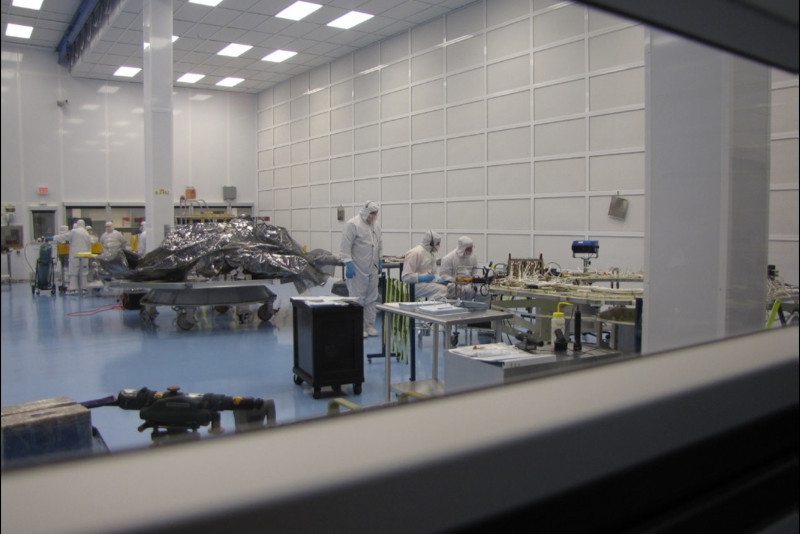

Cleanrooms are designed and operated to maintain a classification of air cleanliness by introducing air

into the room, tent, or bench with conditioned recirculatory or direct ambient air systems through a

series of high efficiency (HEPA) air filters.

The filtered air is maintained at specified velocities in a unidirectional flow pattern that causes contaminants generated within the facility to be carried away in the direction of the moving air stream.

All cleanrooms are certified twice a year to ISO 14644 (2015) standard.

The filtered air is maintained at specified velocities in a unidirectional flow pattern that causes contaminants generated within the facility to be carried away in the direction of the moving air stream.

All cleanrooms are certified twice a year to ISO 14644 (2015) standard.

How We Do It

Cleanrooms are monitored on a periodic basis to verify that the classification of the facility remains

within specification. Cleaning is performed on a predetermined or “as required” schedule based on

classification monitoring results.

Used cleanroom garments are continuously removed from the change rooms and replaced with fresh packaged garments.

Project personnel are present inside the cleanrooms during test activity to ensure that proper cleanroom procedures are followed.

Used cleanroom garments are continuously removed from the change rooms and replaced with fresh packaged garments.

Project personnel are present inside the cleanrooms during test activity to ensure that proper cleanroom procedures are followed.

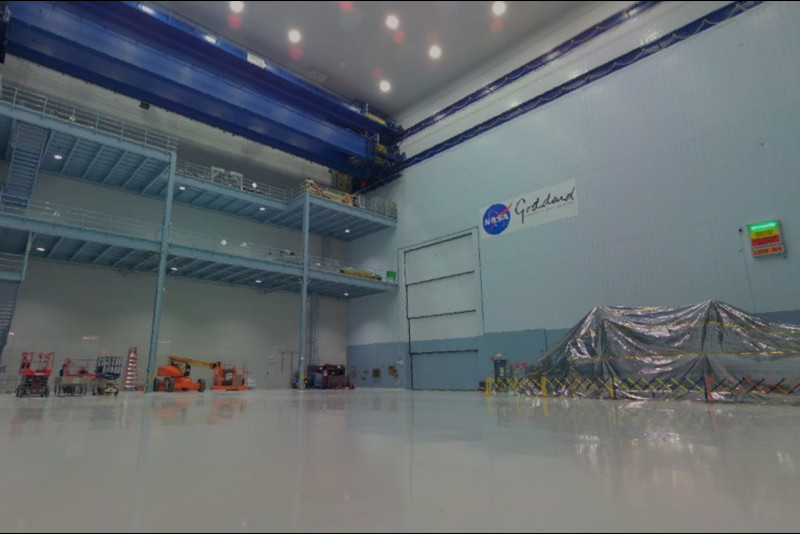

Our Facilities

Additional Services

Particle Counters

Contamination control owns nine (9) portable particle counters that read 0.3, 0.5, 1.0, 3.0, 5.0, 10 um range.

All particle counters are calibrated yearly.

Clean facility certification services are provided bi-annually for clean tents, clean benches, and cleanrooms across the entire GSFC campus, as well as some locations at WFF.

Particle counters are reserved for 549 contamination control use and not continuous room monitoring.

In addition to portable particle counting units, we have permanent continuous monitoring counters installed in the SSDIF and in the White House, with an end goal of installation in all of our hard-walled cleanrooms planned. These particle counters are tied into a remotely accessible database, which allows for 24/7 real-time monitoring of the cleanliness of our facilities.

All particle counters are calibrated yearly.

Clean facility certification services are provided bi-annually for clean tents, clean benches, and cleanrooms across the entire GSFC campus, as well as some locations at WFF.

Particle counters are reserved for 549 contamination control use and not continuous room monitoring.

In addition to portable particle counting units, we have permanent continuous monitoring counters installed in the SSDIF and in the White House, with an end goal of installation in all of our hard-walled cleanrooms planned. These particle counters are tied into a remotely accessible database, which allows for 24/7 real-time monitoring of the cleanliness of our facilities.

Pressure, Temperature, Humidity Monitoring

Cleanroom pressure, temperature, and humidity monitoring is done by a Tridium open-source system in the SCA,

CIA, RFI, 160, White House, and SSDIF cleanrooms.

Contamination control engineering, facility engineering, and maintenance have remote access to the system, and can respond 24/7. Data for these cleanrooms are retained for 5 years minimum but can be changed per project request.

Clean tents and SPOT tents are NOT monitored, unless requested.

In addition to our hardwired controls system, we have temperature and humidity data loggers with remote viewing capabilities located in all of our clean facilities to allow for supplementary monitoring.

Contamination control engineering, facility engineering, and maintenance have remote access to the system, and can respond 24/7. Data for these cleanrooms are retained for 5 years minimum but can be changed per project request.

Clean tents and SPOT tents are NOT monitored, unless requested.

In addition to our hardwired controls system, we have temperature and humidity data loggers with remote viewing capabilities located in all of our clean facilities to allow for supplementary monitoring.

Contamination Monitoring

Continuous contamination monitoring for non-volatile residue (NVR) is performed in all cleanrooms.

Analysis is performed per IEST-STD-CC1246E, and data is trended for all cleanrooms.

Routine NVR monitoring is performed for all I&T complex clean facilities as well as numerous clean facilities outside of the complex.

In situ monitoring is provided upon project request for other testing needs to include thermal vacuum testing and wet silicone operations among others.

Analysis is performed per IEST-STD-CC1246E, and data is trended for all cleanrooms.

Routine NVR monitoring is performed for all I&T complex clean facilities as well as numerous clean facilities outside of the complex.

In situ monitoring is provided upon project request for other testing needs to include thermal vacuum testing and wet silicone operations among others.

CC Analytical Chemistry Lab

The analytical lab has various testing and analysis capabilities to include:

NVR weights

FTIR Spectroscopy

GCMS Analysis (liquid samples)

GC Analysis (gas samples)

Ambient Offgas Analysis

Contamination Mitigation