Thermal Cycling Facility 204 (8 ft³)

Espec EPZ-2H Test Chamber. This facility is a small temperature-controlled chamber used for

thermal conditioning of small components. The portable chamber loads through a front opening door.

Payloads can be installed inside on the floor or on a stainless-steel grated shelf. A port is

available on the left side for instrumentation and connections to ground support equipment, if necessary.

Mode of Operation

The chamber is cooled with a cascade 2.2hp hermetic refrigeration system and heated with electrical resistance elements.

Parameters

Temperature Range

-70°C to +180°C

-70°C to +180°C

Physical Characteristics

Test Volume (W x D x H)

19.7” x 23.6” x 29.5”

(50 x 60 x 75 cm)

19.7” x 23.6” x 29.5”

(50 x 60 x 75 cm)

Access port size

6” (15.24 cm)

6” (15.24 cm)

Power

208 VAC, 3 phase, 40A

208 VAC, 3 phase, 40A

Integral Instrumentation

Temperature is controlled by a digital programmer/controller located on the side of the chamber.

A portable data system may be utilized to monitor the condition of the test articles within.

A portable data system may be utilized to monitor the condition of the test articles within.

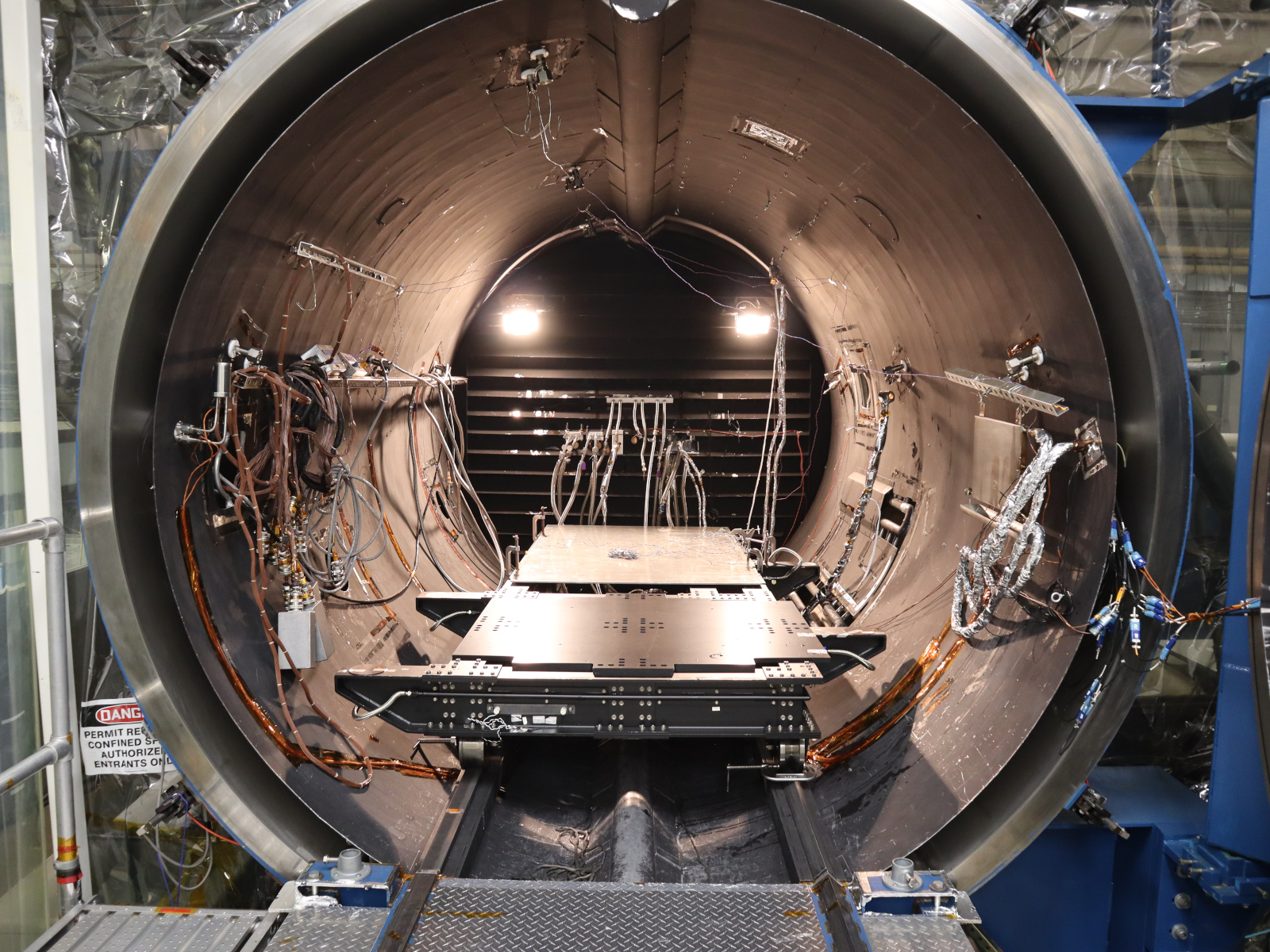

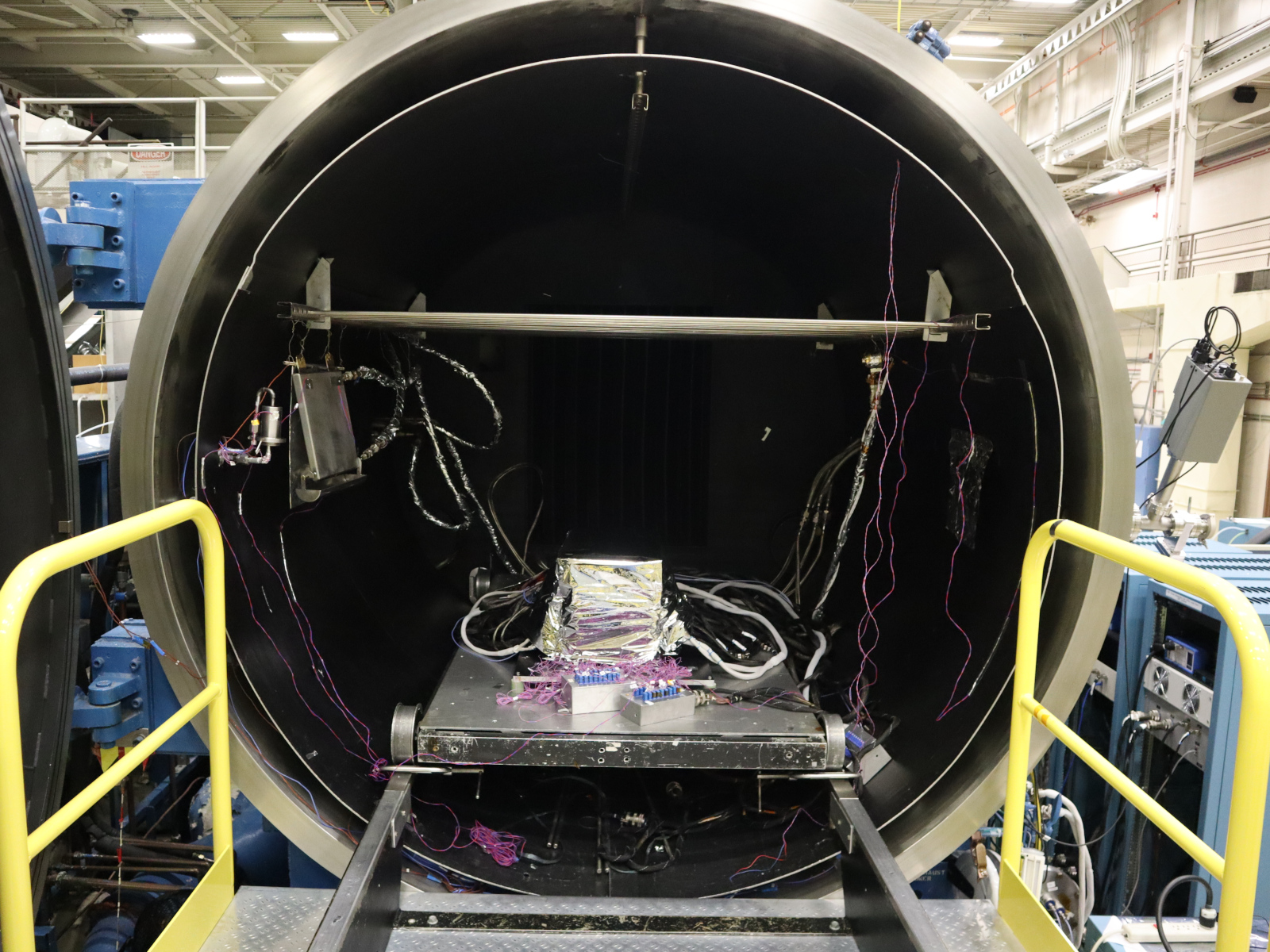

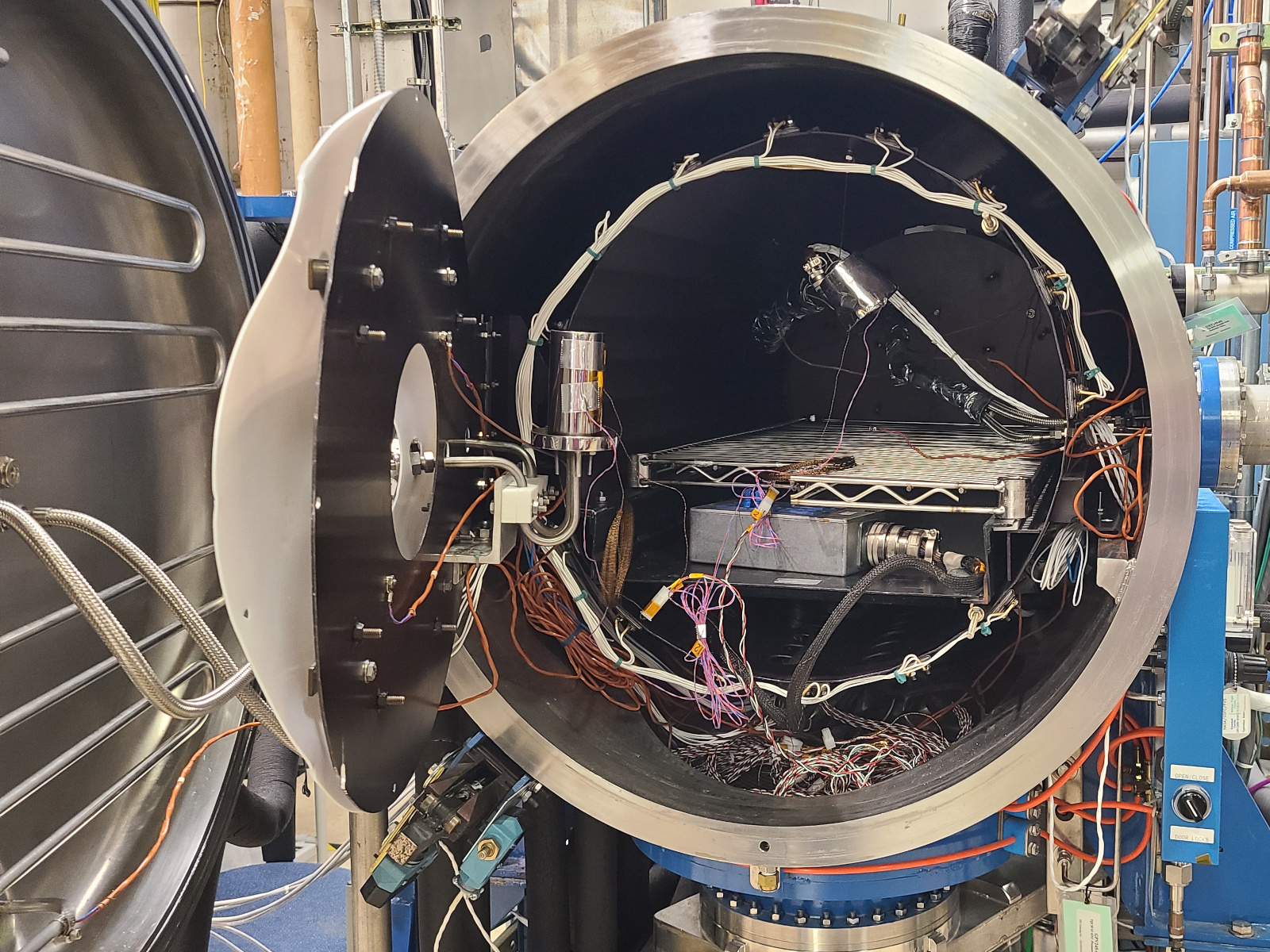

Thermal Vacuum Facility 225 (9’ x 14’)

Facility 225 is a large, horizontal, cylindrical, thermal vacuum chamber used for thermal vacuum and

thermal balance testing, and baking out large test items. Electrical feedthroughs and liquid and gas

penetrations are provided at locations on the front, sides, and rear of the chamber.

A clean tent covering the door opening provides a Class 10,000 clean area for integrating hardware prior to loading it into the chamber.

Mode of Operation

Test items are loaded by crane onto the payload cart, which is rolled into the chamber on a rail system.

The payload cart includes plumbing for auxiliary heating and cooling via a thermal conditioning unit,

and heaters for increased transition rates.

The payload cart can support loads up to 3,000 lbs.

The chamber door remains open while thermocouples are installed on the test item inside the chamber. A temperature controlled baseplate may be provided for high thermal dissipation.

Chamber evacuation is provided by a blower and rotary vane mechanical pump, while high vacuum is achieved using two cryopumps and one turbomolecular pump. Shroud temperature conditioning is accomplished by a recirculating GN2 thermal system or being flooded with LN2.

The chamber door remains open while thermocouples are installed on the test item inside the chamber. A temperature controlled baseplate may be provided for high thermal dissipation.

Chamber evacuation is provided by a blower and rotary vane mechanical pump, while high vacuum is achieved using two cryopumps and one turbomolecular pump. Shroud temperature conditioning is accomplished by a recirculating GN2 thermal system or being flooded with LN2.

Parameters

Test Pressure

< 1 x 10-4 Torr

< 1 x 10-4 Torr

Chamber Pumps

rotary vane mechanical pump, blower, turbomolecular pump, two cryopumps

rotary vane mechanical pump, blower, turbomolecular pump, two cryopumps

Shroud Temperature (GN2 mode)

-142°C to +156°C

-142°C to +156°C

Shroud Temperature (LN2 mode)

< -170°C

< -170°C

Physical Characteristics

Test Volume

9' x 14'

9' x 14'

Payload Support

Wheeled cart - 3,000 lb. capacity

Wheeled cart - 3,000 lb. capacity

Std. electrical feedthroughs

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Paint

MH2200

MH2200

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Payload Temperature

320 thermocouple channels

320 thermocouple channels

Contamination Monitor

TQCM, coldfinger, residual gas analyzer, scavenger plate

TQCM, coldfinger, residual gas analyzer, scavenger plate

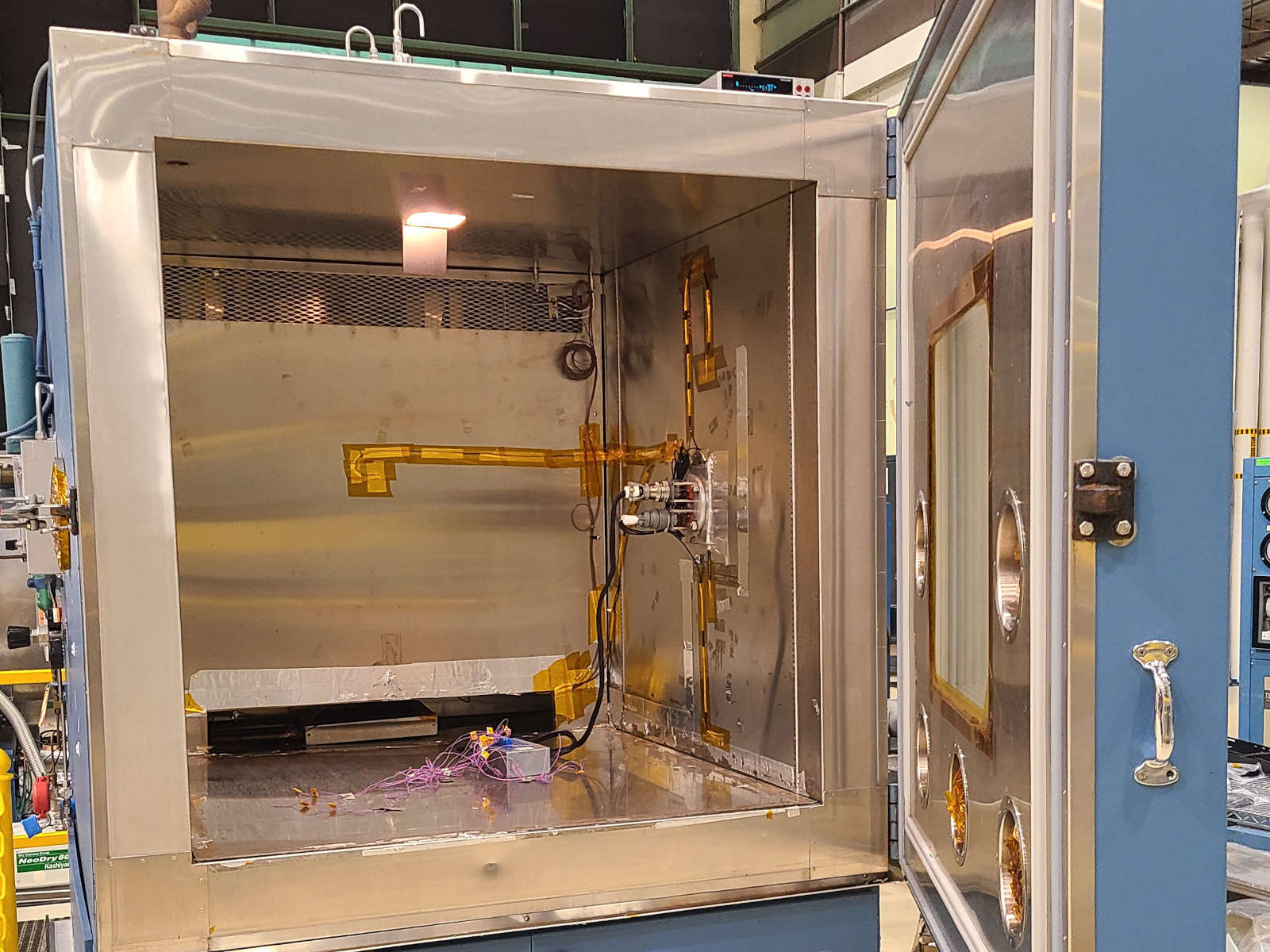

Thermal Cycling Facility 232 (64 ft³)

Facility 232 is a medium-sized chamber used for thermal and humidity cycling of medium-sized test

items. A full-opening, hinged front door with a window allows for access and viewing.

An LN2 boost mode is available that will inject LN2 into the GN2 purge, allowing additional

cooling than what is provided by the cascade refrigeration system.

Mode of Operation

The test item is installed in the chamber and connected to an external power source and data

acquisition equipment via an access port.

After ambient functional checks are completed, electrical heaters warm, and a cascade refrigeration system cools the air stream. A separate cooling unit provides dehumidification, and an electrically heated vapor generator provides humidification.

The preferred procedure is to operate the chamber with a hot cycled before decreasing the temperature below +4°C (+39°F). A dry nitrogen purge system regulates humidity in the chamber to prevent frost build-up on the test item.

Five integral gloves are provided in the front of the chamber for "glovebox" type testing of mechanisms, etc.

After ambient functional checks are completed, electrical heaters warm, and a cascade refrigeration system cools the air stream. A separate cooling unit provides dehumidification, and an electrically heated vapor generator provides humidification.

The preferred procedure is to operate the chamber with a hot cycled before decreasing the temperature below +4°C (+39°F). A dry nitrogen purge system regulates humidity in the chamber to prevent frost build-up on the test item.

Five integral gloves are provided in the front of the chamber for "glovebox" type testing of mechanisms, etc.

Parameters

Temperature Range

-95°C to +150°C

-95°C to +150°C

Humidity Range

15% to 95% (between +85°C max and +4°C min dewpoint)

15% to 95% (between +85°C max and +4°C min dewpoint)

Heating Capacity

18 kW

18 kW

Cooling Capacity

22 kW

22 kW

Physical Characteristics

Test Volume (W x D x H)

48" x 48" x 48"

48" x 48" x 48"

Viewport Size

24" x 24"

24" x 24"

Access Port Size

6"

6"

Integral Instrumentation

Payload Temperature

18 thermocouple channels

18 thermocouple channels

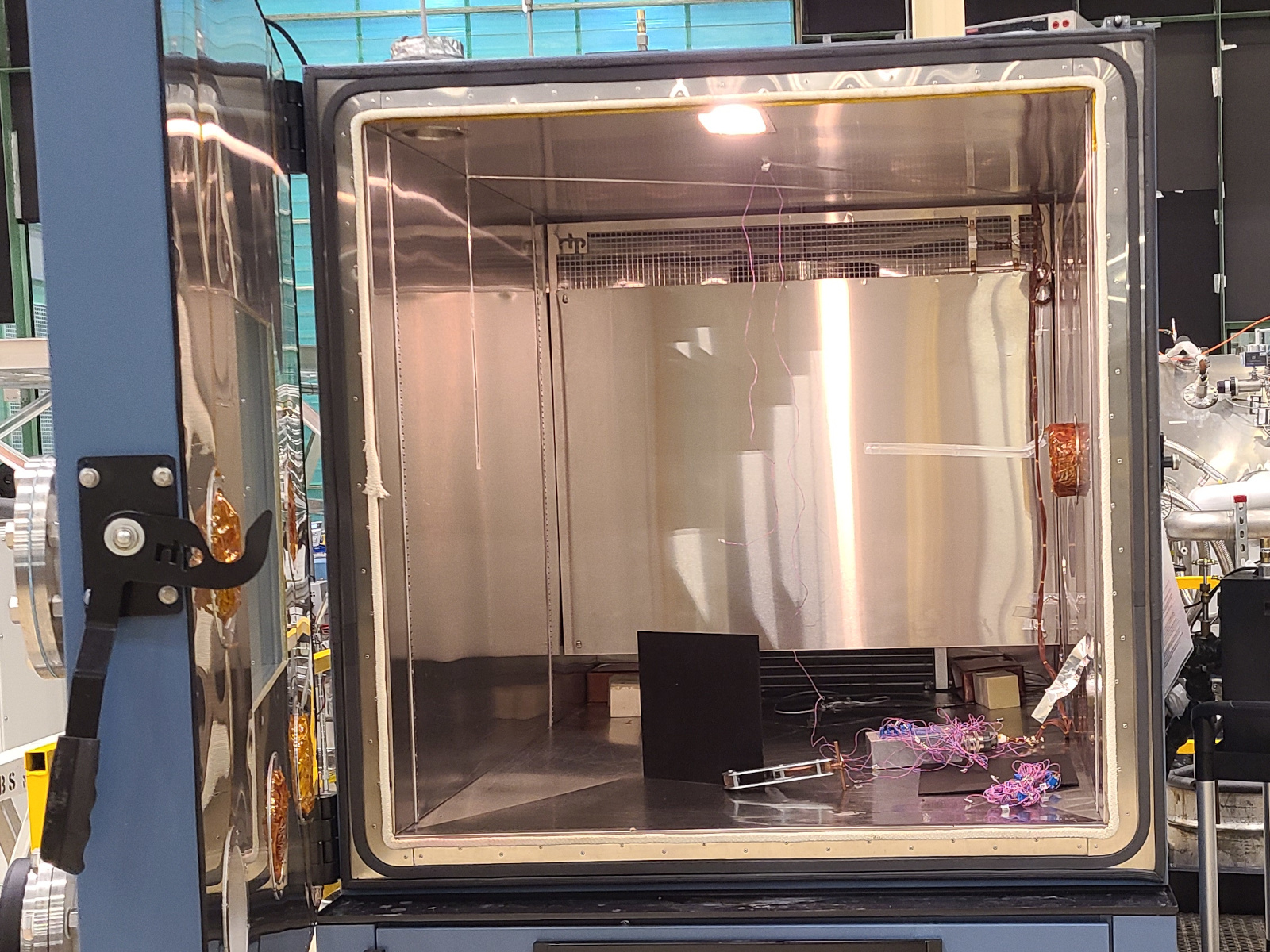

Thermal Cycling Facility 233 (64 ft³)

Facility 233 is a medium-sized chamber used for thermal and humidity cycling of medium-sized test

items. A full-opening, hinged front door with a window allows for access and viewing.

Mode of Operation

The test item is installed in the chamber and connected to an external power source and data

acquisition equipment via an access port.

After ambient functional checks are completed, electrical heaters warm, and a cascade refrigeration system cools the air stream. A separate cooling unit provides dehumidification, and an electrically heated vapor generator provides humidification.

The preferred procedure is to operate the chamber with a hot cycled before decreasing the temperature below +4°C (+39°F). A dry nitrogen purge system regulates humidity in the chamber to prevent frost build-up on the test item.

Two integral gloves are provided in the front of the chamber for "glovebox" type testing of mechanisms, etc.

After ambient functional checks are completed, electrical heaters warm, and a cascade refrigeration system cools the air stream. A separate cooling unit provides dehumidification, and an electrically heated vapor generator provides humidification.

The preferred procedure is to operate the chamber with a hot cycled before decreasing the temperature below +4°C (+39°F). A dry nitrogen purge system regulates humidity in the chamber to prevent frost build-up on the test item.

Two integral gloves are provided in the front of the chamber for "glovebox" type testing of mechanisms, etc.

Parameters

Temperature Range

-65°C to +150°C

-65°C to +150°C

Humidity Range

15% to 95% (between +85°C max and +4°C min dewpoint)

15% to 95% (between +85°C max and +4°C min dewpoint)

Heating Capacity

18 kW

18 kW

Cooling Capacity

22 kW

22 kW

Physical Characteristics

Test Volume (W x D x H)

48" x 48" x 48"

48" x 48" x 48"

Viewport Size

24" x 24"

24" x 24"

Access Port Size

6"

6"

Integral Instrumentation

Payload Temperature

18 thermocouple channels

18 thermocouple channels

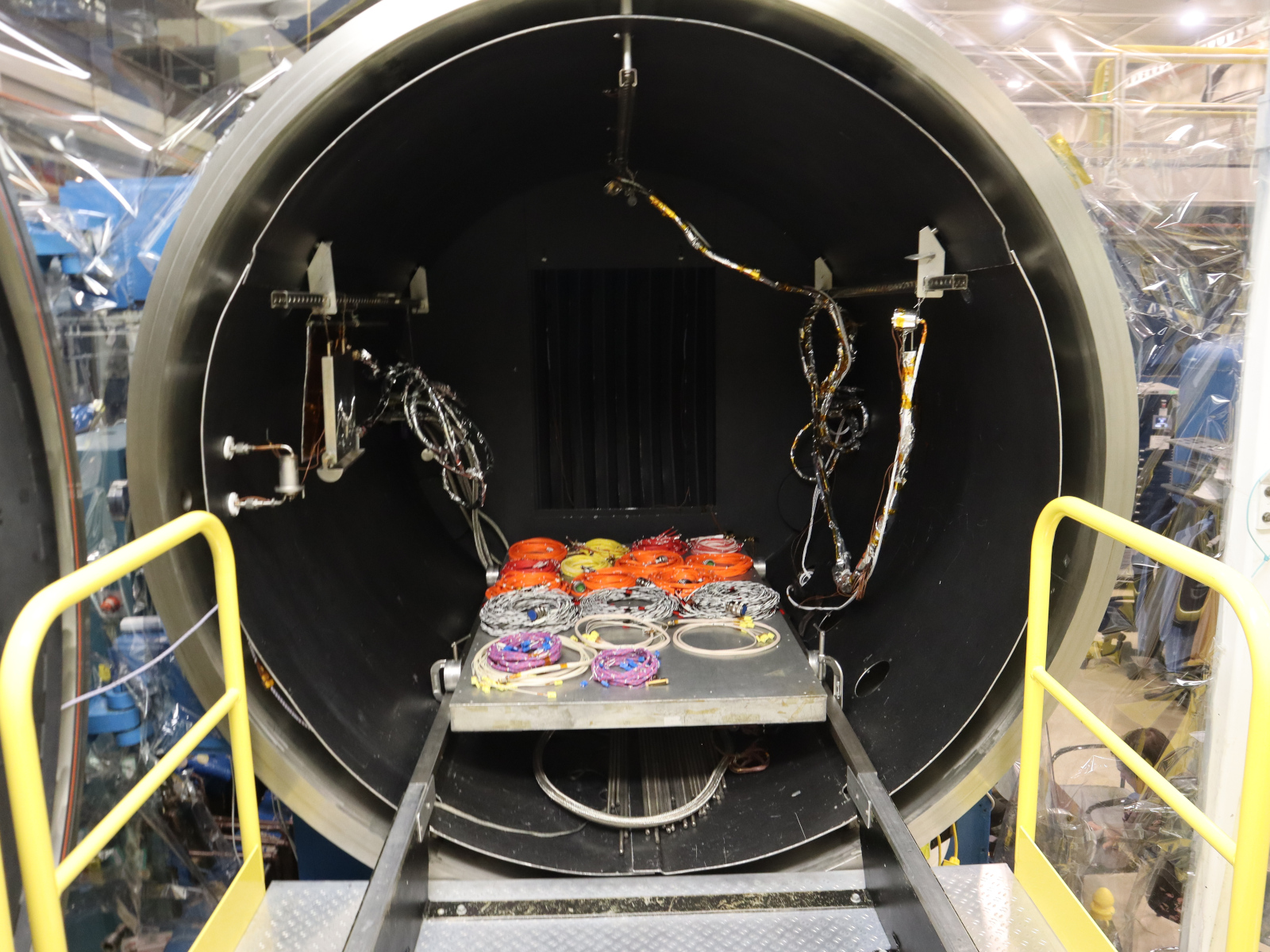

Thermal Vacuum Facility 237 (7’ x 8’)

Facility 237 is a horizontal, medium-sized, thermal vacuum test chamber.

Chamber evacuation is initially provided by a rotary piston mechanical pump and high vacuum is

achieved with an oil diffusion pump. A sliding gate main valve allows chamber access while the

diffusion pump is being established.

The facility is used for thermal vacuum and thermal balance testing, and baking out test items.

Mode of Operation

The test item is mounted on the portable payload cart which is positioned at the chamber door.

An overhead rail is also available for mounting purposes.

The payload is instrumented with thermocouples and rolled into the chamber. Ground support equipment cabling is connected through the penetration plates and ambient functional checks are performed.

Chamber evacuation is provided by a rotary piston mechanical pump and an oil diffusion pump. Rapid pump down can also be performed. A sliding gate main valve allows chamber access while the pumping systems are established.

The payload is instrumented with thermocouples and rolled into the chamber. Ground support equipment cabling is connected through the penetration plates and ambient functional checks are performed.

Chamber evacuation is provided by a rotary piston mechanical pump and an oil diffusion pump. Rapid pump down can also be performed. A sliding gate main valve allows chamber access while the pumping systems are established.

Parameters

Test Pressure

< 1 x 10-5 Torr

< 1 x 10-5 Torr

Chamber Pumps

Oil diffusion pump

Rotary piston mechanical pump

Oil diffusion pump

Rotary piston mechanical pump

Shroud Temperature (GN2 mode)

-140°C to +129°C

-140°C to +129°C

Shroud Temperature (LN2 mode)

< -170°C

< -170°C

Physical Characteristics

Test Volume

7' x 8'

7' x 8'

Payload Support

Wheeled cart - 1288 or 1607 lbs.

Wheeled cart - 1288 or 1607 lbs.

Paint

Cat-A-Lac

(AKA Akzo Nobel 463-3-8)

Cat-A-Lac

(AKA Akzo Nobel 463-3-8)

Std. electrical feedthroughs

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Payload Temperature

106 thermocouple channels

106 thermocouple channels

Contamination Monitor

TQCM, coldfinger, residual gas analyzer, scavenger plate

TQCM, coldfinger, residual gas analyzer, scavenger plate

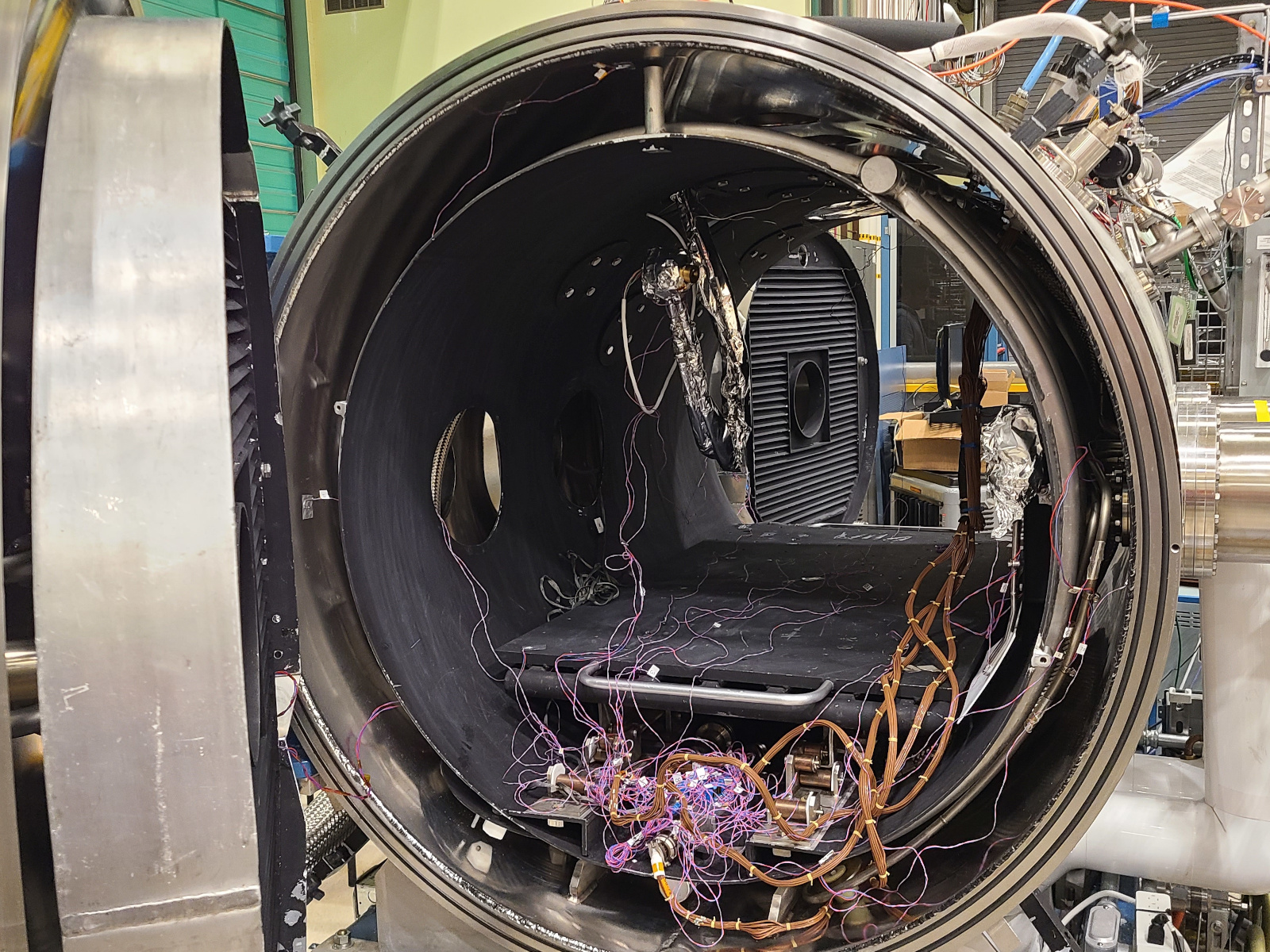

Thermal Vacuum Facility 238 (12’ x 14’)

Facility 238 is a large, vertical, cylindrical thermal vacuum chamber which is used for thermal vacuum and thermal

balance testing, and baking out spacecraft hardware. Test articles are normally loaded through the top of the chamber

using the building crane; however, small payloads can be transported through the personnel entrance. Ports for

electrical feedthroughs and liquid/gas feedthroughs are located around the perimeter of the chamber.

A clean tent at the chamber entrance provides class 10,000 cleanliness conditions.

Mode of Operation

With the chamber dome rolled back, the overhead crane is used to lower the payload onto the support fixture.

Once installed, the payload is instrumented and connected to the ground support equipment via feedthroughs.

Access to the chamber is through a clean tent. The use of cleanroom procedures and the wearing of clean garments are required when working in the chamber.

Initial chamber evacuation is provided by two rotary piston mechanical pumps and two blowers, with three closed cycle cryopumps and one turbomolecular pump for high vacuum pumping. Each cryopump is isolated from the chamber by a sliding gate main valve to allow off-line cool down and regeneration.

Once installed, the payload is instrumented and connected to the ground support equipment via feedthroughs.

Access to the chamber is through a clean tent. The use of cleanroom procedures and the wearing of clean garments are required when working in the chamber.

Initial chamber evacuation is provided by two rotary piston mechanical pumps and two blowers, with three closed cycle cryopumps and one turbomolecular pump for high vacuum pumping. Each cryopump is isolated from the chamber by a sliding gate main valve to allow off-line cool down and regeneration.

Parameters

Test Pressure

< 1 x 10-6 Torr

< 1 x 10-6 Torr

Chamber Pumps

Three cryopumps

Two rotary piston mechanical pumps

One turbomolecular pump

Three cryopumps

Two rotary piston mechanical pumps

One turbomolecular pump

Shroud Temperature (GN2 mode)

-118°C to +114°C

-118°C to +114°C

Shroud Temperature (LN2 mode)

< -170°C

< -170°C

Physical Characteristics

Test Volume

12' x 15'

12' x 15'

Payload Support

10’ diameter payload table 20,000 lbs

Vertical Hardpoints on chamber wall 1,000 lbs

10’ diameter payload table 20,000 lbs

Vertical Hardpoints on chamber wall 1,000 lbs

Crane Capacity

5 tons

5 tons

Paint

Cat-A-Lac

(AKA Akzo Nobel 463-3-8)

Cat-A-Lac

(AKA Akzo Nobel 463-3-8)

Std. electrical feedthroughs

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Payload Temperature

324 channels of thermocouple or thermistor channels

324 channels of thermocouple or thermistor channels

Contamination Monitor

TQCM, coldfinger, residual gas analyzer, scavenger plate

TQCM, coldfinger, residual gas analyzer, scavenger plate

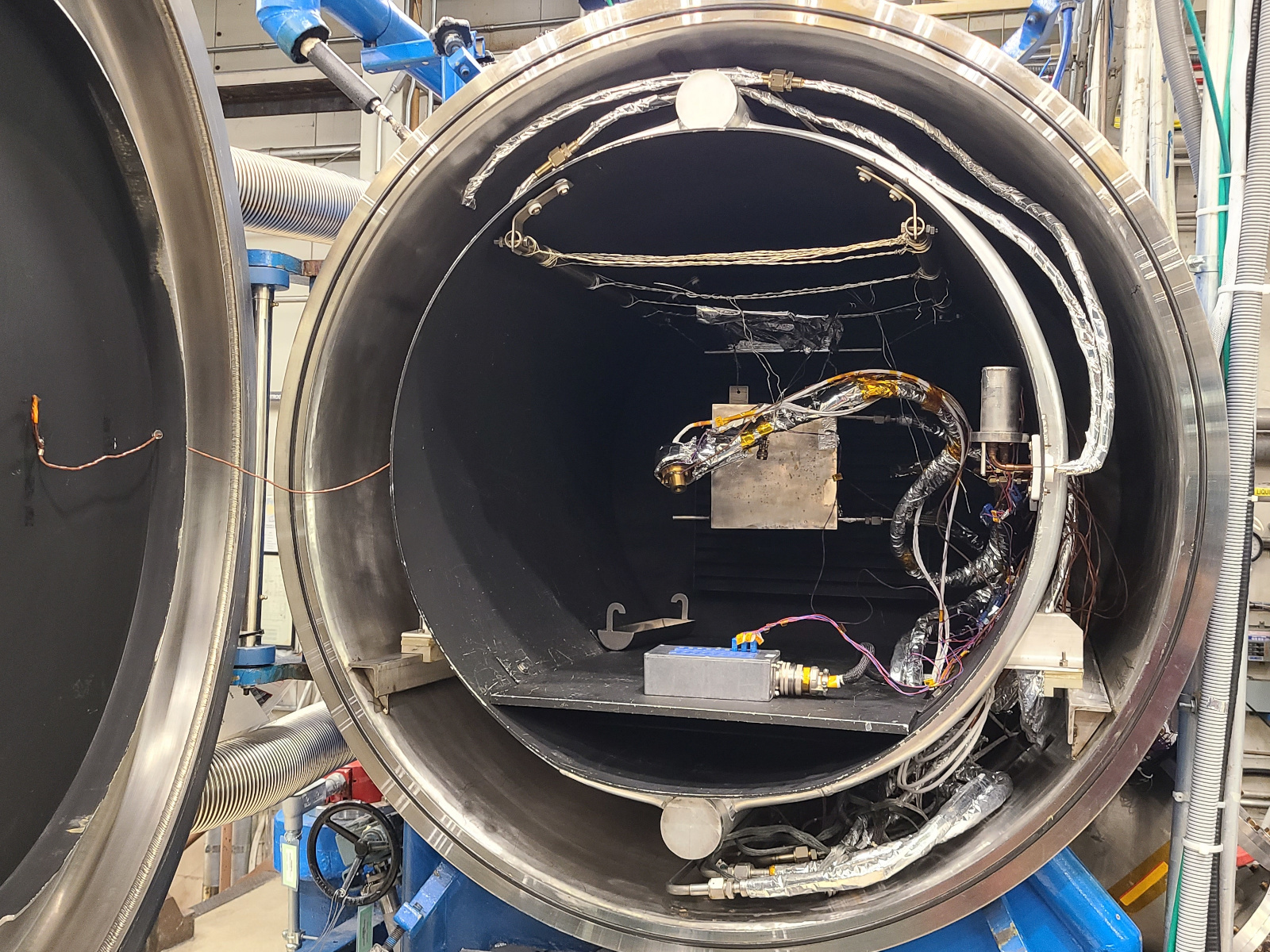

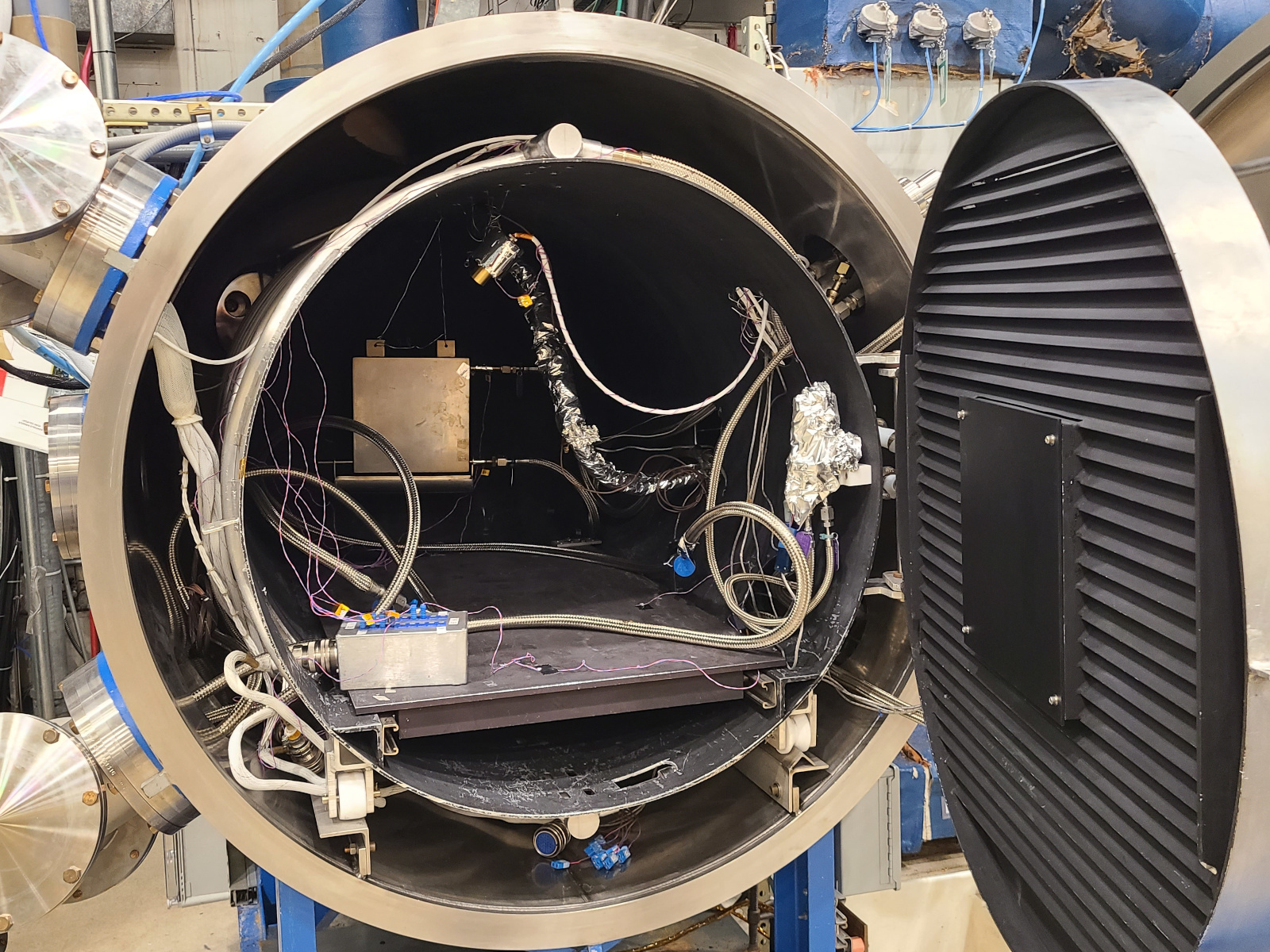

Thermal Vacuum Facility 239 (7’ x 8’)

Facility 239 is a horizontal, medium-sized, thermal vacuum test chamber.

Chamber evacuation is provided by a rotary piston mechanical pump and cryopumping system.

A sliding gate main valve allows chamber access while the cryopumping system is being established.

The facility is used for thermal vacuum and thermal balance testing, and baking out test items.

A clean tent at the chamber entrance provides class 10,000 cleanliness conditions.

Mode of Operation

The test item is mounted on the portable payload cart which is positioned at the chamber door.

An overhead rail is also available for mounting purposes.

After instrumenting the payload with thermocouples, it is rolled into the chamber. Ground support equipment cabling is connected through the penetration plates and ambient functional checks are performed.

After instrumenting the payload with thermocouples, it is rolled into the chamber. Ground support equipment cabling is connected through the penetration plates and ambient functional checks are performed.

Parameters

Test Pressure

< 1 x 10-5 Torr

< 1 x 10-5 Torr

Chamber Pumps

rotary piston mechanical pump, cryopump

rotary piston mechanical pump, cryopump

Shroud Temperature (GN2 mode)

-148°C to +117°C

-148°C to +117°C

Physical Characteristics

Test Volume

7' x 8'

7' x 8'

Payload Support

Wheeled cart - 1288 or 1607 lbs.

Wheeled cart - 1288 or 1607 lbs.

Paint

Cat-A-Lac

(AKA Akzo Nobel 463-3-8)

Cat-A-Lac

(AKA Akzo Nobel 463-3-8)

Std. electrical feedthroughs

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Payload Temperature

106 thermocouple channels

106 thermocouple channels

Contamination Monitor

TQCM, coldfinger, residual gas analyzer, scavenger plate

TQCM, coldfinger, residual gas analyzer, scavenger plate

Thermal Vacuum Facility 240 (3’ x 3’)

Facility 240 is a horizontal, cylindrical, small-sized, diffusion pumped thermal vacuum test chamber used

for thermal vacuum testing and bakeout of test articles. The payload is mounted on a plate which is supported

by rails welded to the chamber wall.

Mode of Operation

After the test article is instrumented with thermocouples and placed in the chamber, ground

support equipment cabling is connected through the penetration plates, and ambient functional

checks are performed.

Placing the test article on a baseplate or suspending it from the overhead rail are acceptable mounting methods.

Chamber evacuation is provided by rotary piston mechanical pumps and an oil diffusion pump. A main valve allows test set up while the pumping system is being established.

Placing the test article on a baseplate or suspending it from the overhead rail are acceptable mounting methods.

Chamber evacuation is provided by rotary piston mechanical pumps and an oil diffusion pump. A main valve allows test set up while the pumping system is being established.

Parameters

Test Pressure

< 1 x 10-5 Torr

< 1 x 10-5 Torr

Shroud Temperature

-107°C to +116°C

-107°C to +116°C

Chamber Pumps

rotary piston mechanical pump, diffusion pump

rotary piston mechanical pump, diffusion pump

Physical Characteristics

Test Volume

3' x 3'

3' x 3'

Payload Support

Payload Table – 1854 lbs.

Payload Table – 1854 lbs.

Paint

Z306

Z306

Std. electrical feedthroughs

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Payload Temperature

36 thermocouple channels

36 thermocouple channels

Contamination Monitor

TQCM, coldfinger, residual gas analyzer, scavenger plate

TQCM, coldfinger, residual gas analyzer, scavenger plate

Thermal Vacuum Facility 241 (3’ x 4’)

Facility 241 is a horizontal, cylindrical, medium-sized, thermal vacuum test chamber used for thermal vacuum

testing and baking out test articles.

The payload table has a 4” x 4” grid with 1/4-20 mounting holes to secure the hardware.

The payload table includes piping that is plumbed in with the chamber shroud to help speed payload transitions.

Mode of Operation

After the test article is instrumented with thermocouples and installed in the chamber, it is connected to the ground

support equipment and data acquisition system via electrical feedthroughs.

After roughing down the chamber with the mechanical pump, ultimate pressure is achieved with the cryopump. A main valve allows test set up while the pumping system is being established.

After roughing down the chamber with the mechanical pump, ultimate pressure is achieved with the cryopump. A main valve allows test set up while the pumping system is being established.

Parameters

Test Pressure

< 1 x 10-6 Torr

< 1 x 10-6 Torr

Shroud Temperature

-150°C to +150°C

-150°C to +150°C

Chamber Pumps

rotary piston mechanical pump, cryopump

rotary piston mechanical pump, cryopump

Physical Characteristics

Test Volume

3' x 4'

3' x 4'

Payload Support

Payload Table - 500 lbs.

Payload Table - 500 lbs.

Paint

MH2200

MH2200

Std. electrical feedthroughs

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Payload Temperature

36 thermocouple channels

36 thermocouple channels

Contamination Monitor

TQCM, coldfinger, residual gas analyzer, scavenger plate

TQCM, coldfinger, residual gas analyzer, scavenger plate

Thermal Vacuum Facility 245 (2’ x 3’)

Facility 245 is a horizontal, cylindrical turbomolecular pumped thermal vacuum test chamber used for bakeout of small test articles.

The chamber is heated with electrical resistance elements and does not have native cooling capabilities.

The payload is placed on a rack that is supported by rails.

Mode of Operation

After the test article is instrumented with thermocouples and placed in the chamber, ground support equipment

cabling is connected through penetration plates and ambient functional checks are performed.

After roughing down the chamber with the rotary piston mechanical pump, ultimate pressure is achieved with the turbomolecular pump.

After roughing down the chamber with the rotary piston mechanical pump, ultimate pressure is achieved with the turbomolecular pump.

Parameters

Test Pressure

< 1 x 10-5 Torr

< 1 x 10-5 Torr

Shroud Temperature

+20°C to +145°C

+20°C to +145°C

Chamber Pumps

turbomolecular pump

turbomolecular pump

Physical Characteristics

Test Volume

21" x 40"

21" x 40"

Payload Support

Payload Table - 200 lbs.

Payload Table - 200 lbs.

Shroud Coating

Black Anodized

Black Anodized

Std. electrical feedthroughs

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Contamination Monitor

TQCM, coldfinger, residual gas analyzer

TQCM, coldfinger, residual gas analyzer

Thermal Vacuum Facility 246 (3.5’ x 4.5’)

Facility 246 is a horizontal, cylindrical, medium-sized, thermal vacuum test chamber used for thermal

vacuum testing and baking out test articles.

The payload table has a 4” x 4” grid with 1/4-20 mounting holes to secure the hardware.

The payload table includes piping that is plumbed in with the chamber shroud to help speed payload transitions.

The chamber includes doors at opposite ends of the chamber.

Mode of Operation

After the test article is instrumented with thermocouples and installed in the chamber,

it is connected to the ground support equipment and data acquisition system via electrical feedthroughs.

After roughing down the chamber with the mechanical pump, ultimate pressure is achieved with the cryopump. A main valve allows test set up while the pumping system is being established.

The chamber includes doors on opposite ends of the chamber to improve accessibility to payloads.

After roughing down the chamber with the mechanical pump, ultimate pressure is achieved with the cryopump. A main valve allows test set up while the pumping system is being established.

The chamber includes doors on opposite ends of the chamber to improve accessibility to payloads.

Parameters

Test Pressure

< 1 x 10-6 Torr

< 1 x 10-6 Torr

Chamber Pumps

oil-free mechanical pump, cryopump

oil-free mechanical pump, cryopump

Shroud Temperature

-140°C to +150°C

-140°C to +150°C

Physical Characteristics

Test Volume

3.5’ x 5.5’

3.5’ x 5.5’

Payload support

Payload Table – 500 lbs.

Payload Table – 500 lbs.

Paint

MH2200

MH2200

Std. electrical feedthroughs

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

61-pin, 37-pin, 7-pin, 4-pin, RF

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Payload Temperature

36 thermocouple channels

36 thermocouple channels

Contamination Monitor

Cold finger, scavenger plate, TQCM, residual gas analyzer

Cold finger, scavenger plate, TQCM, residual gas analyzer

Thermal Vacuum Facility 281 (3’ x 4’)

Facility 281 is a horizontal, cylindrical, medium-sized, thermal vacuum test chamber used for thermal

vacuum testing and baking out test articles.

The payload is placed on the payload table which can slide out to help with installation.

Mode of Operation

After the test article is instrumented with thermocouples and installed in the chamber,

it is connected to the ground support equipment and data acquisition system via electrical feedthroughs.

After roughing down the chamber with the mechanical pump, ultimate pressure is achieved with the cryopump. A main valve allows test set up while the pumping system is being established.

After roughing down the chamber with the mechanical pump, ultimate pressure is achieved with the cryopump. A main valve allows test set up while the pumping system is being established.

Parameters

Test Pressure

< 1 x 10-6 Torr

< 1 x 10-6 Torr

Chamber Pumps

rotary piston mechanical pump, cryopump

rotary piston mechanical pump, cryopump

Shroud Temperature (GN2 mode)

-140°C to +150°C

-140°C to +150°C

Shroud Temperature (LN2 mode)

< -170°C

< -170°C

Physical Characteristics

Test Volume

3' x 4'

3' x 4'

Payload support

Payload Table – 760 lbs.

Payload Table – 760 lbs.

Paint

Cat-A-Lac

(AKA Akzo Nobel 463-3-8)

Cat-A-Lac

(AKA Akzo Nobel 463-3-8)

Standard Electrical Feedthroughs

36 - 37 pin connectors

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

36 - 37 pin connectors

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Payload Temperature

36 thermocouple channels

36 thermocouple channels

Contamination Monitor

TQCM, coldfinger, cryocoil, residual gas analyzer, scavenger plate

TQCM, coldfinger, cryocoil, residual gas analyzer, scavenger plate

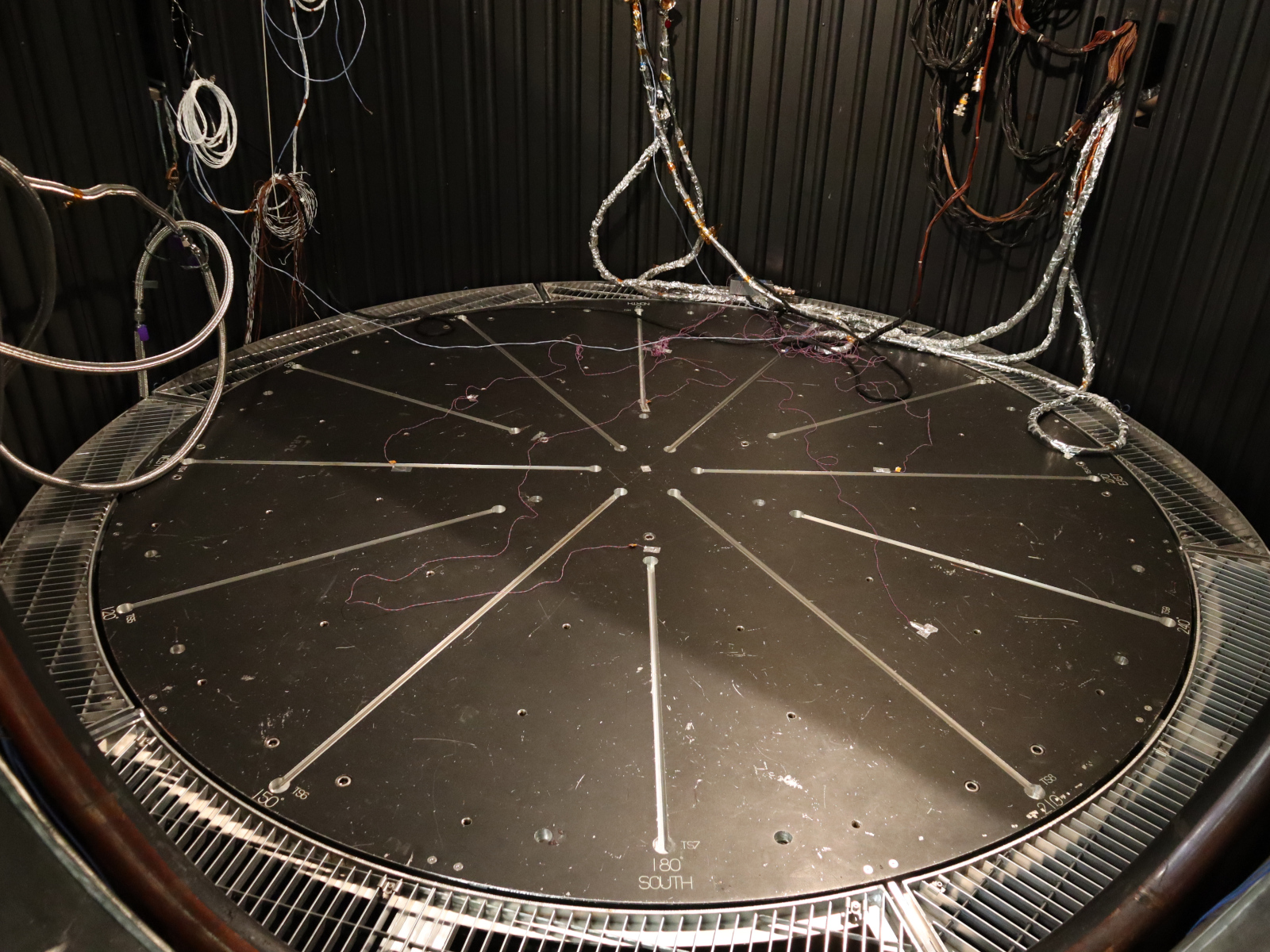

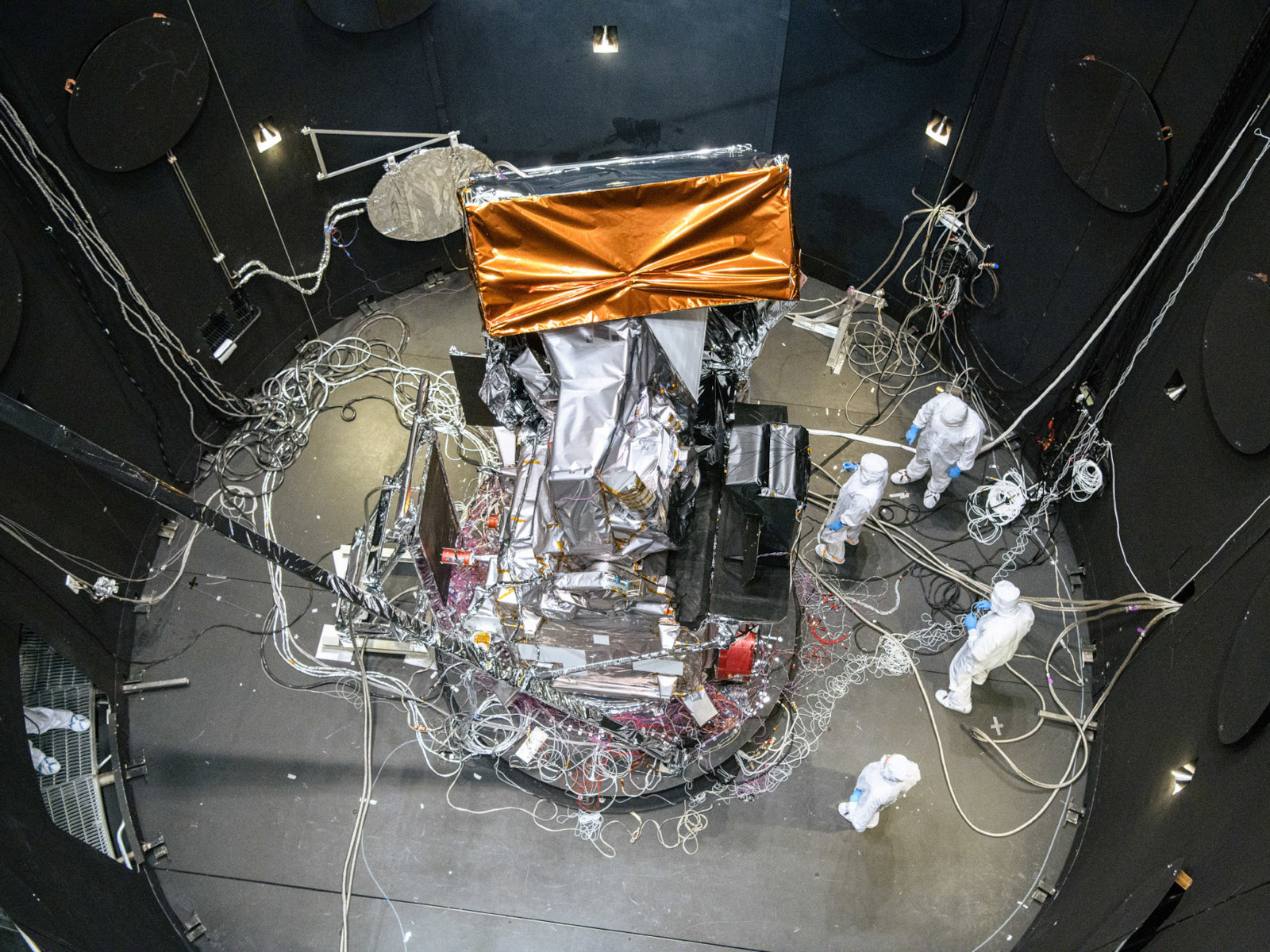

Thermal Vacuum Facility 290 (27' x 40')

Facility 290 (AKA the Space Environment Simulator or SES) is a vertical, very large thermal vacuum test chamber capable of

achieving ultra-low pressure and a wide range of thermal conditions.

Test articles are loaded through the top of the chamber using the building 10 crane and personnel entry is through

an access port in the basement.

The chamber is used for thermal vacuum and thermal balance testing and baking out very large test articles.

Mode of Operation

The test article is loaded onto the payload table or internal fixturing with the chamber dome rolled back.

Often, special fixturing is required.

An external clean air supply provides fresh air to the chamber during pre-test activities.

Entry to instrument the payload with thermocouples, connect ground support equipment cabling, and install hardware is through a cleanroom airshower at the personnel door. Wearing of clean room garments is required.

Scaffolding may be erected to provide access to the payload. An area adjacent to the main facility control console is reserved for the experimenter's ground support equipment. Ambient functional checks are normally performed.

Payloads are typically installed on the 10’ diameter payload table in the center of the chamber, while ground support equipment (GSE) rests on the bottom shroud or optional personnel grates, when installed. Verify that your test article and/or GSE can be supported with a Code 549 Space Simulation Test Engineer during the planning phase.

During temperature cycling, soak periods are observed for functional checks as specified in the test plan. A computer data terminal is provided with packaged software routines for temperature monitoring.

Chamber evacuation is provided by eight rotary piston mechanical pumps with Roots blowers, and eight cryopumps. Two turbomolecular pumps are available to pump the lighter gases to achieve ultra-low pressures.

Thermal control is provided by an aluminum tube-in-sheet cylindrical shroud with both liquid nitrogen and gaseous nitrogen operational modes. The dome and bottom shrouds are also connected to the thermal skids. The payload table includes tubing, which can also be connected to the shroud thermal system, controlled independently by a thermal conditioning unit, or flooded with LN2.

Resistance heater arrays, with external power supplies or gaseous nitrogen panels, are available for special thermal requirements. A thermoelectric quartz crystal microbalance (TQCM) and residual gas analyzer (RGA) provide both quantitative and qualitative monitoring of molecular contamination and gaseous constituents within the chamber. A helium refrigeration system can be used to cool auxiliary shrouds or cryopanels to temperatures as low as -253°C (20°K).

Vacuum compatible cameras are available for monitoring the test article.

An external clean air supply provides fresh air to the chamber during pre-test activities.

Entry to instrument the payload with thermocouples, connect ground support equipment cabling, and install hardware is through a cleanroom airshower at the personnel door. Wearing of clean room garments is required.

Scaffolding may be erected to provide access to the payload. An area adjacent to the main facility control console is reserved for the experimenter's ground support equipment. Ambient functional checks are normally performed.

Payloads are typically installed on the 10’ diameter payload table in the center of the chamber, while ground support equipment (GSE) rests on the bottom shroud or optional personnel grates, when installed. Verify that your test article and/or GSE can be supported with a Code 549 Space Simulation Test Engineer during the planning phase.

During temperature cycling, soak periods are observed for functional checks as specified in the test plan. A computer data terminal is provided with packaged software routines for temperature monitoring.

Chamber evacuation is provided by eight rotary piston mechanical pumps with Roots blowers, and eight cryopumps. Two turbomolecular pumps are available to pump the lighter gases to achieve ultra-low pressures.

Thermal control is provided by an aluminum tube-in-sheet cylindrical shroud with both liquid nitrogen and gaseous nitrogen operational modes. The dome and bottom shrouds are also connected to the thermal skids. The payload table includes tubing, which can also be connected to the shroud thermal system, controlled independently by a thermal conditioning unit, or flooded with LN2.

Resistance heater arrays, with external power supplies or gaseous nitrogen panels, are available for special thermal requirements. A thermoelectric quartz crystal microbalance (TQCM) and residual gas analyzer (RGA) provide both quantitative and qualitative monitoring of molecular contamination and gaseous constituents within the chamber. A helium refrigeration system can be used to cool auxiliary shrouds or cryopanels to temperatures as low as -253°C (20°K).

Vacuum compatible cameras are available for monitoring the test article.

Parameters

Test Pressure

< 10-6 Torr

< 10-6 Torr

Chamber Pumps

8 Cryopumps, turbomolecular pump

8 Cryopumps, turbomolecular pump

Shroud Temperature (GN2 mode)

-80°C to +80°C

-80°C to +80°C

Shroud Temperature (LN2 mode)

< -170°C

< -170°C

Physical Characteristics

Test Volume

27' x 40'

27' x 40'

Payload support

Payload Table: 40,000 lbs.

Bottom (Floor) Shroud: 125 pounds per square foot

Personnel Grates: 100 pounds per square foot

Payload Table: 40,000 lbs.

Bottom (Floor) Shroud: 125 pounds per square foot

Personnel Grates: 100 pounds per square foot

Standard Electrical Feedthroughs

37-pin, 7-pin, 4-pin, RF connectors

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

37-pin, 7-pin, 4-pin, RF connectors

Other feedthroughs available (please consult a Code 549 Space Simulation Test Engineer)

Integral Instrumentation

Pressure

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Capacitance Manometer: Atm to 10-3 Torr

Ion Gauge: 10-3 Torr to ultimate

Ion Gauge

10-3 Torr to ultimate

10-3 Torr to ultimate

Payload Temperature

756 thermocouple channels

756 thermocouple channels

Contamination Monitor

TQCM, coldfinger, residual gas analyzer

TQCM, coldfinger, residual gas analyzer